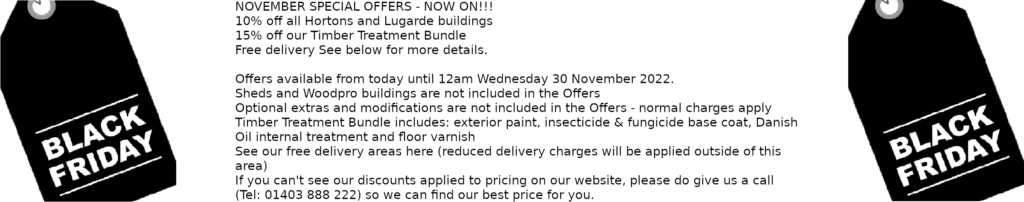

Black Friday sale prices on all Hortons log cabins , Corner cabins, timber gazebos and Easibuild framed buildings AND all Lugarde summerhouses, gazebos and log cabins.

Click the links above to view our range of garden buildings on sale (you will be redirected to our master website (hortonsgroup.com). Alternatively, view some of our log cabins and garden buildings on our general page on this website.

What buildings are in our Black Friday sale?

We have lots of garden building included in our sale including all sizes and specifications of our massive range of log cabins. Everything from small 3x2m log cabins up to 6x13m multi room log cabins. We have lots of options available, some of which are also in our Black Friday deal as well.

All of our “Easibuild” heavy duty garden sheds, workshops, summerhouses and insulated garden offices are also included in this sale. If you are looking to buy an insulated garden room, now is the time to grab yourself a bargain. We have many styles for this type of building including our garden room. All of our Easibuild garden buildings can be installed and insulated. WE are also able to carry out any base work requirements as well.

Not only are Hortons own brand buildings on sale but also Lugarde summerhouses, wooden gazebos and garden cabins as well. You can generate your ideal garden building on the Lugarde configurator and whatever price it generates, we will discount it by 10%.

We’re here to help – on the phone, by email or in person

All of these Black Friday deals are available online and also if you choose to visit our showground in person. So you will still receive the sale price if you would rather see and walk around our products. And you can chat with us if you need help or advice before you decide on your building.

Click here to see all of our contact details and our showground location