We supply beautiful hand crafted, modern timber greenhouses. Our versatile range can be tailored to your individual requirements and is available to customers nationwide. We take great care in manufacturing our greenhouses which are installed by our expert installation technicians. In this way we are confident that your new Coppice Collection greenhouse will be installed to your complete satisfaction.

At Coppice you will find a dedicated team of specialist craft people committed to every stage of the design, build, delivery and installation of your greenhouse. Our friendly team have in-depth product knowledge and will guide you through every stage, from initial enquiry to installation.

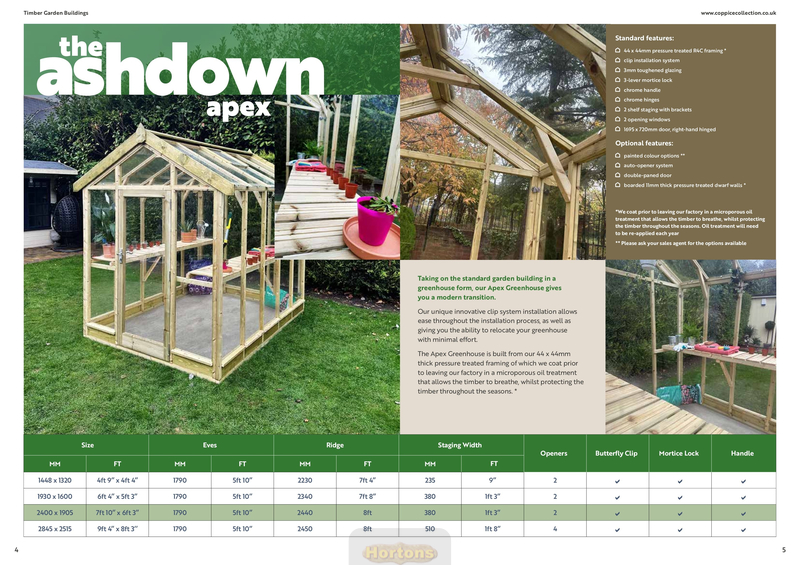

The Ashdown Timber greenhouses range

Taking on the standard garden building in a greenhouse form, our Apex Timber Greenhouses give

you a modern transition. Our unique innovative clip system installation allows ease throughout the installation process, as well as giving you the ability to relocate your greenhouse with minimal effort.

The Ashdown apex timber greenhouse has 44 x 44mm thick pressure treated framing of which we coat prior to leaving our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber throughout the seasons.

- Standard Ashdown features:

- 44 x 44mm pressure treated R4C framing *

- clip installation system

- 3mm toughened glazing

- 3-lever mortice lock

- chrome handle

- chrome hinges

- 2 shelf staging with brackets

- 2 opening windows

- 1695 x 720mm door, right-hand hinged

Optional features:

- painted colour options

- auto-opener system

- double-paned door

- boarded 11mm thick pressure treated dwarf walls *

*We coat prior to leaving our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber throughout the seasons. Oil treatment will needs re-applying each year

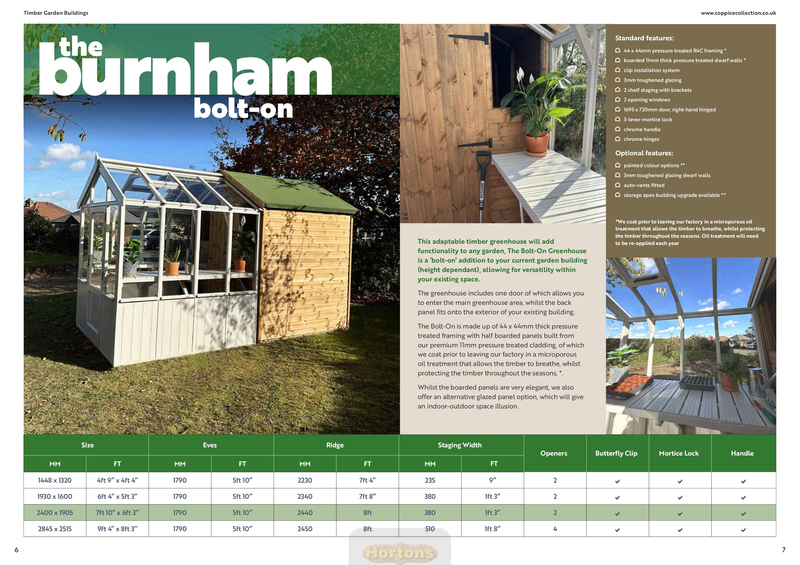

The Burnham Bolt-on Timber Greenhouses range

This adaptable timber greenhouse will add functionality to any garden. The Bolt-On Greenhouse is a ‘bolt-on’ addition to your current garden building (height dependant), allowing for versatility within your existing space.

The greenhouse includes one door of which allows you to enter the main greenhouse area, whilst the back panel fits onto the exterior of your existing building. The Bolt-On is made up of 44 x 44mm thick pressure treated framing with half boarded panels built from our premium 11mm pressure treated cladding, of which we coat prior to leaving our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber throughout the seasons. *.

Whilst the boarded panels are very elegant, we also offer an alternative glazed panel option, which will give an indoor-outdoor space illusion.

Standard features:

- 44 x 44mm pressure treated R4C framing *

- boarded 11mm thick pressure treated dwarf walls *

- clip installation system

- 3mm toughened glazing

- 2 shelf staging with brackets

- 2 opening windows

- 1695 x 720mm door, right-hand hinged

- 3-lever mortice lock

- chrome handle

- chrome hinges

Optional features:

- painted colour options

- 3mm toughened glazing dwarf walls

- auto-vents fitted

- storage apex building upgrade available **

*We coat prior to leaving our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber throughout the seasons. Oil treatment will needs re-applying each year

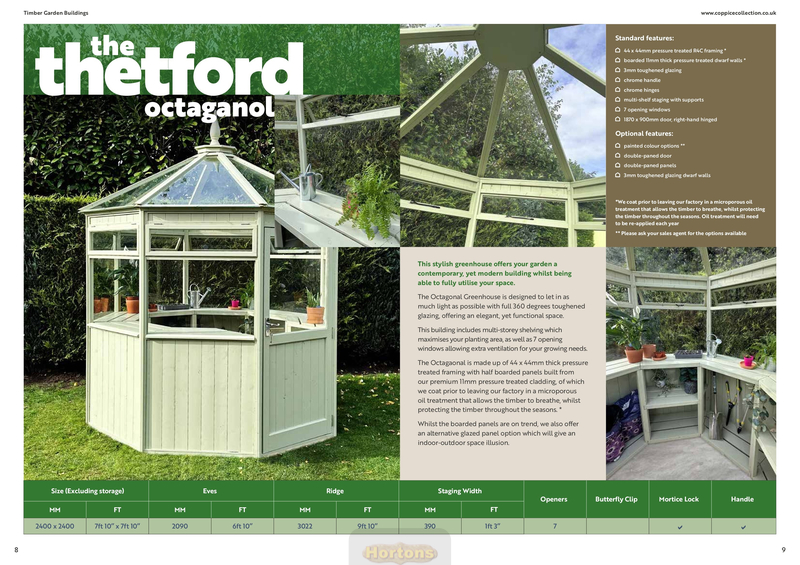

Thetford Octagonal Greenhouses

This stylish greenhouse offers your garden a contemporary, yet modern building whilst being able to fully utilise your space. The Octagonal Greenhouse lets in as much light as possible with full 360 degrees toughened glazing, offering an elegant, yet functional space. This building includes multi-storey shelving which maximises your planting area, as well as 7 opening windows allowing extra ventilation for your growing needs.

The Octagonal is made up of 44 x 44mm thick pressure treated framing with half board height panels built from our premium 11mm pressure treated cladding, of which we coat prior to leaving our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber throughout the seasons. *

Whilst the boarded panels are on trend, we also offer an alternative glazed panel option which will give an indoor-outdoor space illusion.

Standard features:

- 44 x 44mm pressure treated R4C framing *

- boarded 11mm thick pressure treated dwarf walls *

- 3mm toughened glazing

- chrome handle

- chrome hinges

- multi-shelf staging with supports

- 7 opening windows

- 1870 x 900mm door, right-hand hinged

Optional features:

- painted colour options

- double-paned door

- double-paned panels

- 3mm toughened glazing dwarf walls

*We coat prior to leaving our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber throughout the seasons. Oil treatment will needs re-applying each year

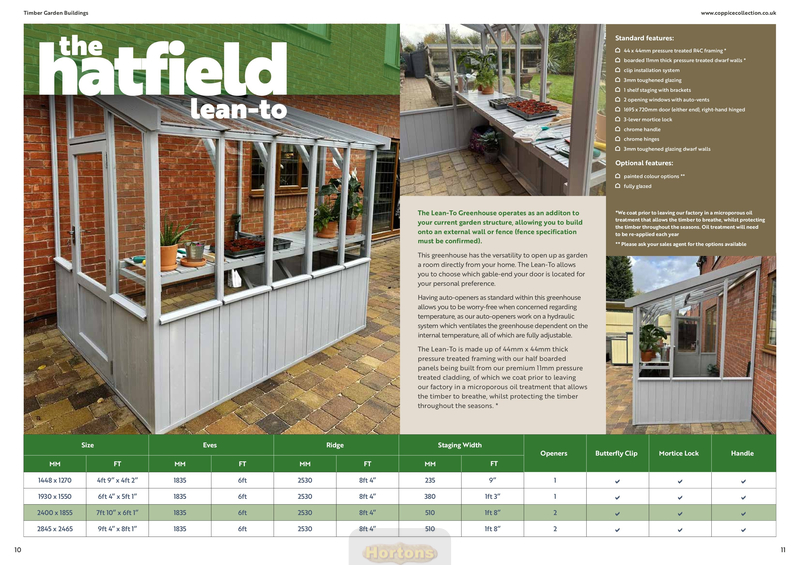

Hatfield Lean-to greenhouses

The Lean-To Greenhouse operates as an addition to your current garden structure, allowing you to build

onto an external wall or fence (fence specification must be suitable).

This greenhouse has the versatility to open up as garden a room directly from your home. The Lean-To allows you to choose which gable-end your door is located for your personal preference.

Having auto-openers as standard within this greenhouse allows you to be worry-free when concerned regarding temperature, as our auto-openers work on a hydraulic system which ventilates the greenhouse dependent on the internal temperature, all of which are fully adjustable.

The Lean-To framing is 44mm x 44mm thick pressure treated framing with our half boarded panels from our premium 11mm pressure treated cladding, of which we coat prior to leaving

our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber

throughout the seasons. *

Standard features:

- 44 x 44mm pressure treated R4C framing *

- boarded 11mm thick pressure treated dwarf walls *

- clip installation system

- 3mm toughened glazing

- 1 shelf staging with brackets

- 2 opening windows with auto-vents

- 1695 x 720mm door (either end), right-hand hinged

- 3-lever mortice lock

- chrome handle

- chrome hinges

- 3mm toughened glazing dwarf walls

Optional features:

- painted colour options

- fully glazed

*We coat prior to leaving our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber throughout the seasons. Oil treatment needs re-applying each year

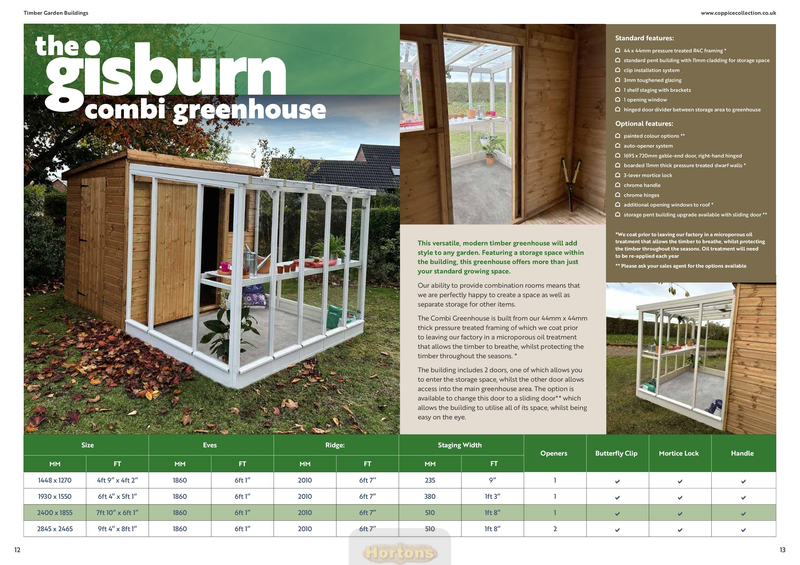

Gisburn Combi Timber Greenhouses

This versatile, modern timber greenhouse will add style to any garden. Featuring a storage space within

the building, this greenhouse offers more than just your standard growing space.

Our ability to provide combination rooms means that we are perfectly happy to create a space as well as

separate storage for other items. The Combi Greenhouse has 44mm x 44mm thick pressure treated framing of which we coat prior to leaving our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber throughout the seasons. *

The building includes 2 doors, one of which allows you to enter the storage space, whilst the other door allows access into the main greenhouse area. The option is available to change this door to a sliding door** which allows the building to utilise all of its space, whilst being easy on the eye.

Standard features:

- 44 x 44mm pressure treated R4C framing *

- standard pent building with 11mm cladding for storage space

- clip installation system

- 3mm toughened glazing

- 1 shelf staging with brackets

- 1 opening window

- hinged door divider between storage area to greenhouse

Optional features:

- painted colour options **

- auto-opener system

- 1695 x 720mm gable-end door, right-hand hinged

- boarded 11mm thick pressure treated dwarf walls *

- 3-lever mortice lock

- chrome handle

- chrome hinges

- additional opening windows to roof *

- storage pent building upgrade available with sliding door **

*We coat prior to leaving our factory in a microporous oil treatment that allows the timber to breathe, whilst protecting the timber throughout the seasons. Oil treatment will need to be re-applied each year

** Please contact us for the options available

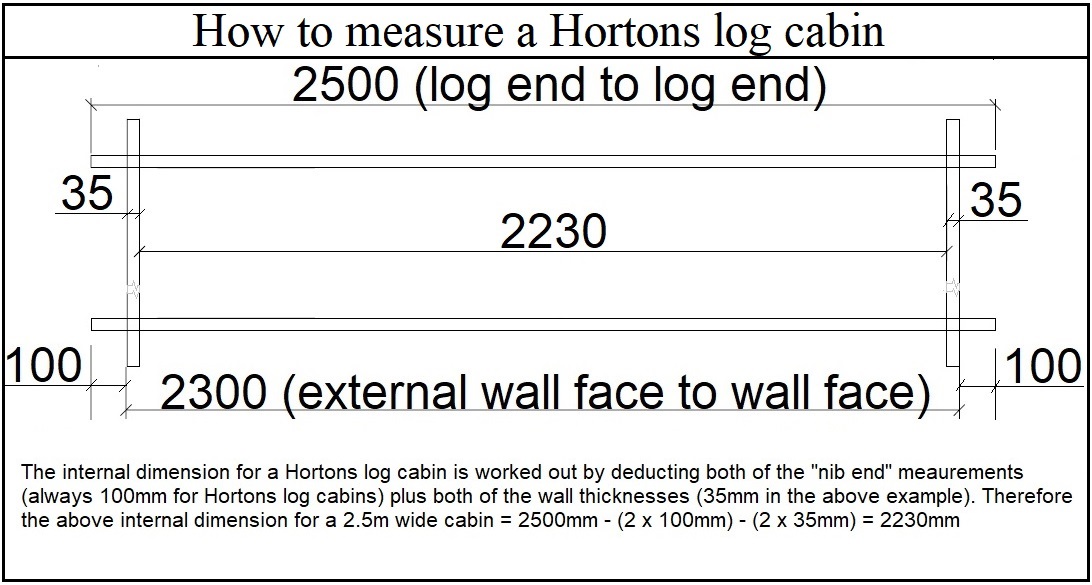

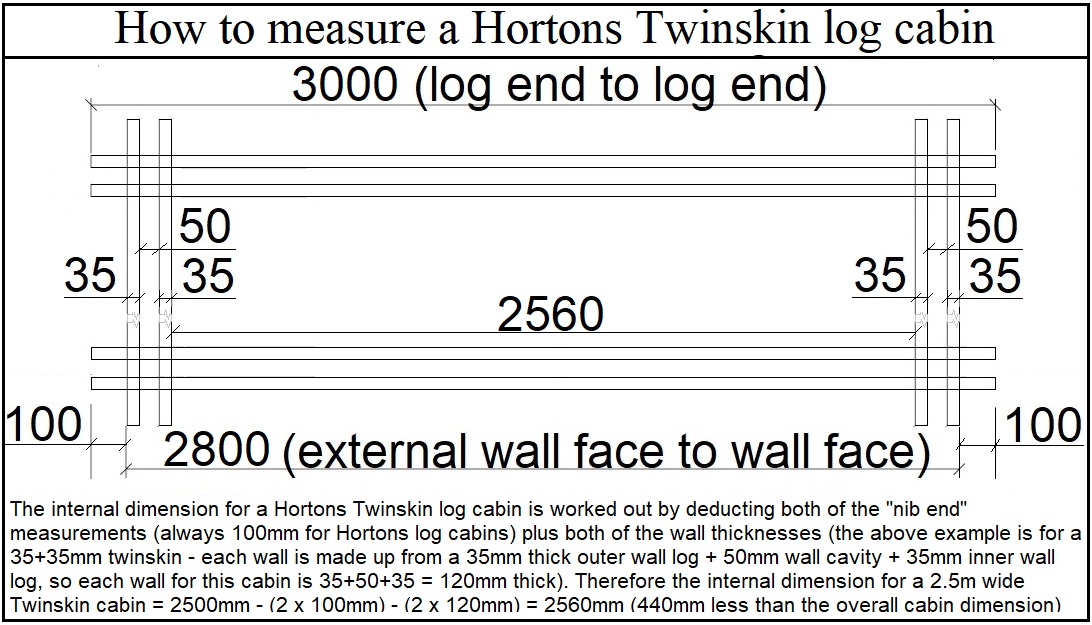

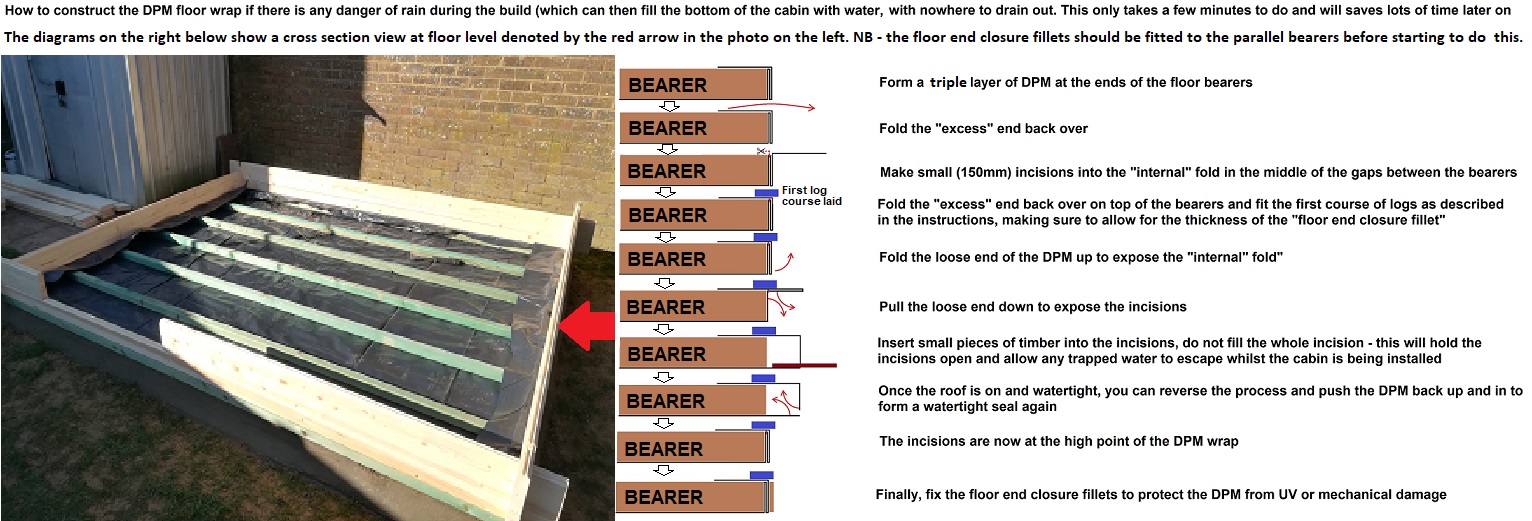

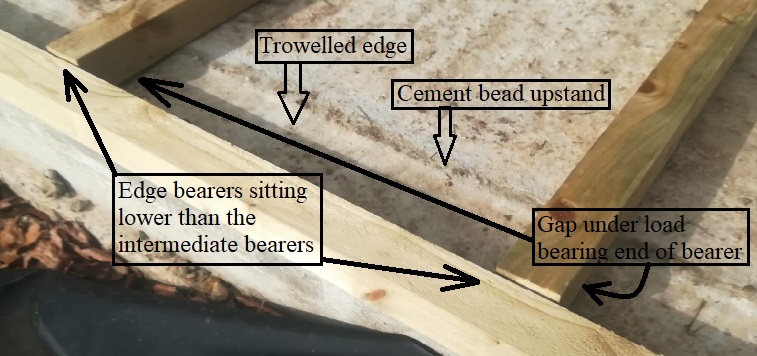

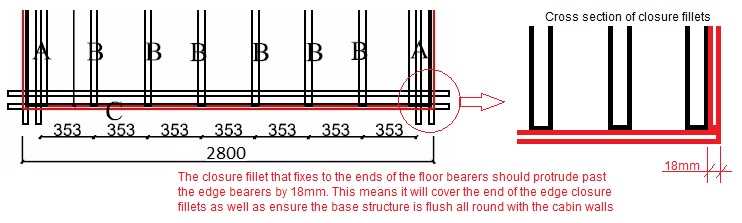

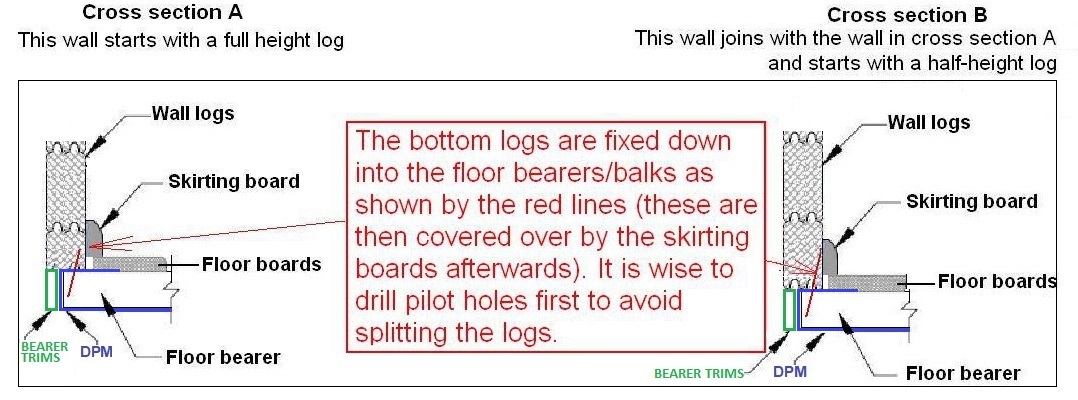

This plan shows a typical floor bearer layout for a cabin with an overall dimension of 3.0m – you should refer to your own set of plans for the exact layout of these for your cabin. If you have an insulated floor, a 19mm thick timber edging piece is supplied to fix along the ends of the bearers to close the ends off (there are no air voids with an insulated floor and therefore no ventilation is required). The interlocking wall log notch is typically set in by 0.1m from each log end, hence the base measuring 2.8m. Please note that the plan shows the spacing between each of the bearers as well as the width of the bearer on plan view. Floor bearers are always laid “flatways” in order to allow for the floorboards to be fitted at the end of the job as described later on. Please note that they are called floor bearers and not floor joists, this is because they are designed to be supported by a sub-base. They are not designed to take the full load and span from one side of the building to the other.It is good practice to lay a damp proof membrane (DPM) on top of your base before starting to install the building (we offer this as an option with our buildings). The DPM should be cut about 200mm larger than the base size required for the cabin , it can then be folded over on top of the floor bearers and trapped by the bearer trims supplied with our DPM kit to hold it in position (our floor bearers are pre-cut lengths to allow for this and the bearers should also be spaced such that they finish 20mm inside the wall face to allow for the trims when they are fitted, this then ensures that the DPM trims finish flush with the walls so they don’t trap water on top of them). This means that should water get on top of your base and under the building, the water will stay under the DPM rather than get on top of it, keeping all of the timber and insulation (if you have any within the floor structure) dry. If you do not have an insulated floor, ventilation holes can then be cut sufficiently above the base level, if required, to keep the standing water at bay (no ventilation required with a warm deck insulated floor). Please turn subtitles on when watching the following DPM installation video –

This plan shows a typical floor bearer layout for a cabin with an overall dimension of 3.0m – you should refer to your own set of plans for the exact layout of these for your cabin. If you have an insulated floor, a 19mm thick timber edging piece is supplied to fix along the ends of the bearers to close the ends off (there are no air voids with an insulated floor and therefore no ventilation is required). The interlocking wall log notch is typically set in by 0.1m from each log end, hence the base measuring 2.8m. Please note that the plan shows the spacing between each of the bearers as well as the width of the bearer on plan view. Floor bearers are always laid “flatways” in order to allow for the floorboards to be fitted at the end of the job as described later on. Please note that they are called floor bearers and not floor joists, this is because they are designed to be supported by a sub-base. They are not designed to take the full load and span from one side of the building to the other.It is good practice to lay a damp proof membrane (DPM) on top of your base before starting to install the building (we offer this as an option with our buildings). The DPM should be cut about 200mm larger than the base size required for the cabin , it can then be folded over on top of the floor bearers and trapped by the bearer trims supplied with our DPM kit to hold it in position (our floor bearers are pre-cut lengths to allow for this and the bearers should also be spaced such that they finish 20mm inside the wall face to allow for the trims when they are fitted, this then ensures that the DPM trims finish flush with the walls so they don’t trap water on top of them). This means that should water get on top of your base and under the building, the water will stay under the DPM rather than get on top of it, keeping all of the timber and insulation (if you have any within the floor structure) dry. If you do not have an insulated floor, ventilation holes can then be cut sufficiently above the base level, if required, to keep the standing water at bay (no ventilation required with a warm deck insulated floor). Please turn subtitles on when watching the following DPM installation video –

The logs are joined in the middle of a partition wall or portal archway. The metal plate is supplied in long lengths which can be cut to length on site with snips or hacksaw. The joining logs should be tightly clamped and then fixed using a screw through the metal plate either side of the joint which will stop the logs spreading in the future (these screws should be angled away from each other slightly as this will pull the joint together and also increases the pulling strength of the screws). Every course of logs should be joined in this way.

The logs are joined in the middle of a partition wall or portal archway. The metal plate is supplied in long lengths which can be cut to length on site with snips or hacksaw. The joining logs should be tightly clamped and then fixed using a screw through the metal plate either side of the joint which will stop the logs spreading in the future (these screws should be angled away from each other slightly as this will pull the joint together and also increases the pulling strength of the screws). Every course of logs should be joined in this way.

AND (or can be a combination of both if required)

AND (or can be a combination of both if required)

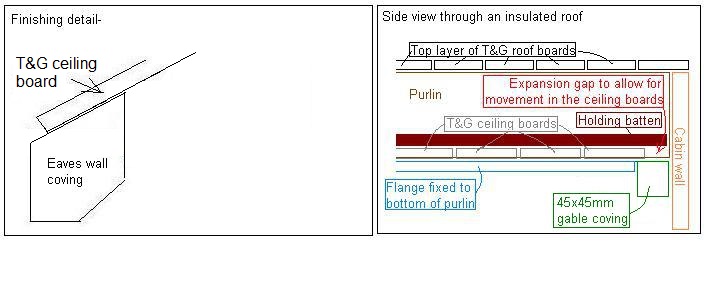

If you are installing electric wires (ie lighting circuit), this is the perfect time to do this as there is full and easy access to all areas required within the roof void.

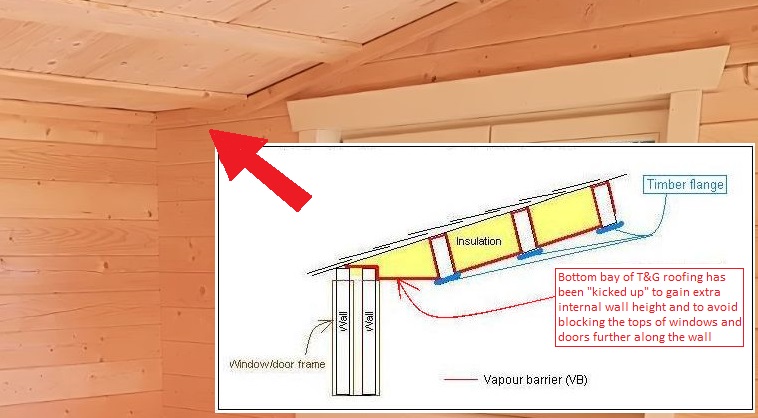

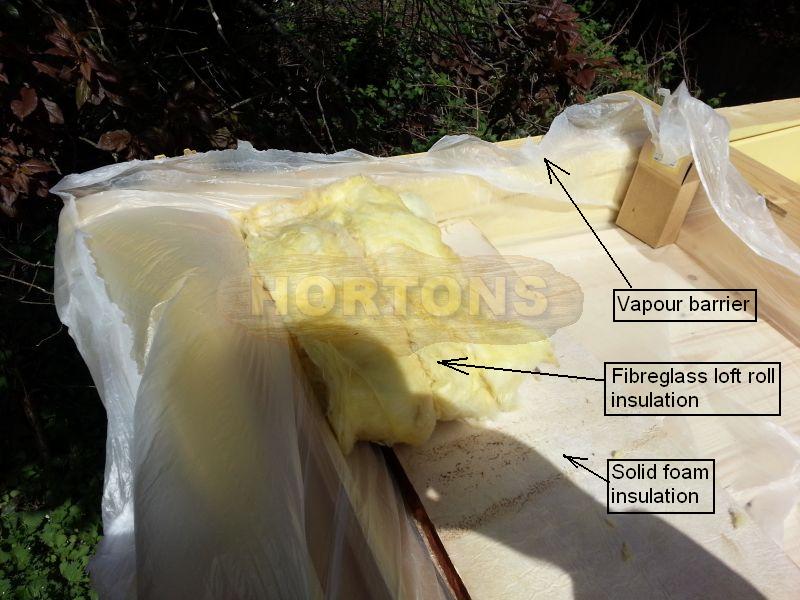

If you are installing electric wires (ie lighting circuit), this is the perfect time to do this as there is full and easy access to all areas required within the roof void. Insert your insulation into each bay, if you have a solid foam board and fibreglass loft roll combination mix, then lay the solid foam board in first (make sure it is a tight fit and sits tight against the ceiling boards), then lay the loftroll on top to fully fill the bay up to the top of the purlins. If you have the fibreglass only kit, the roof requires 2 layers of the loftroll to be rolled out (the fibrglass insulation kit also comes with 50mm thick slabs, these are for the floor, and walls if you have a twinskin cabin). This photo shows a cut-away version depicting the various layers-

Insert your insulation into each bay, if you have a solid foam board and fibreglass loft roll combination mix, then lay the solid foam board in first (make sure it is a tight fit and sits tight against the ceiling boards), then lay the loftroll on top to fully fill the bay up to the top of the purlins. If you have the fibreglass only kit, the roof requires 2 layers of the loftroll to be rolled out (the fibrglass insulation kit also comes with 50mm thick slabs, these are for the floor, and walls if you have a twinskin cabin). This photo shows a cut-away version depicting the various layers-

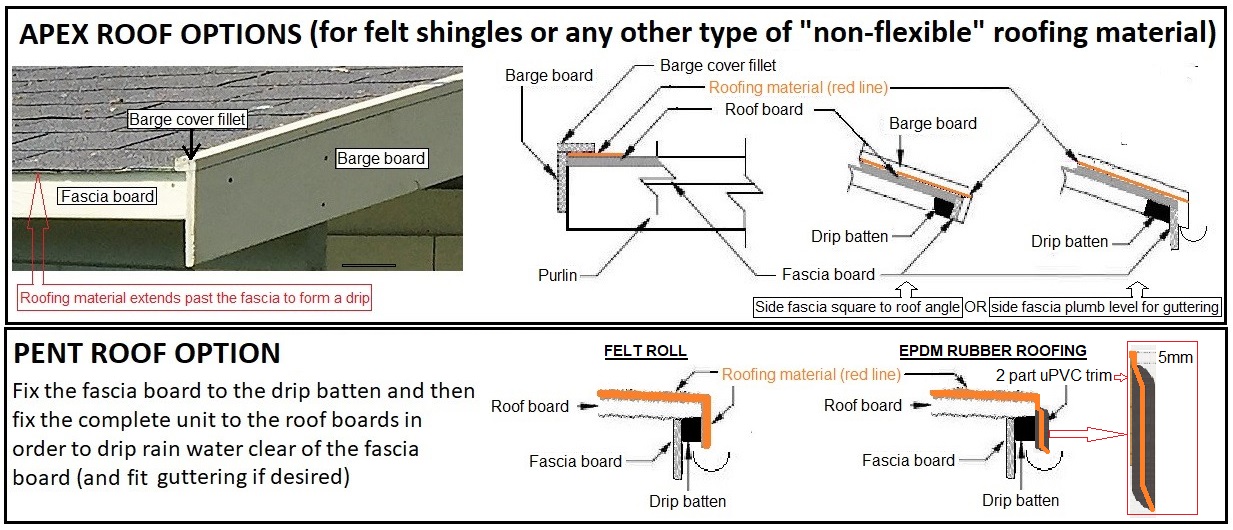

Once the roofing material (felt roll, felt shingles, etc) has been fitted, the barge boards (and fascias if felt roll) can be fitted which helps to hold the felt down. (Installation of other roofing materials, ie felt shingles / recycled rubber roof tiles / onduvilla, will vary slightly from the above method – please refer to the installation guide for that specific product if it is relevant). It is easiest to fit the barge cover fillet to the barge board (to form an upside down L shape) before fixing the complete barge unit to the roof. If you have double height barge boards (made of of 2 pieces of timber with a tongue & groove connection), then fit the upper L shaped piece first as just described, and then fit the lower piece afterwards.

Once the roofing material (felt roll, felt shingles, etc) has been fitted, the barge boards (and fascias if felt roll) can be fitted which helps to hold the felt down. (Installation of other roofing materials, ie felt shingles / recycled rubber roof tiles / onduvilla, will vary slightly from the above method – please refer to the installation guide for that specific product if it is relevant). It is easiest to fit the barge cover fillet to the barge board (to form an upside down L shape) before fixing the complete barge unit to the roof. If you have double height barge boards (made of of 2 pieces of timber with a tongue & groove connection), then fit the upper L shaped piece first as just described, and then fit the lower piece afterwards.